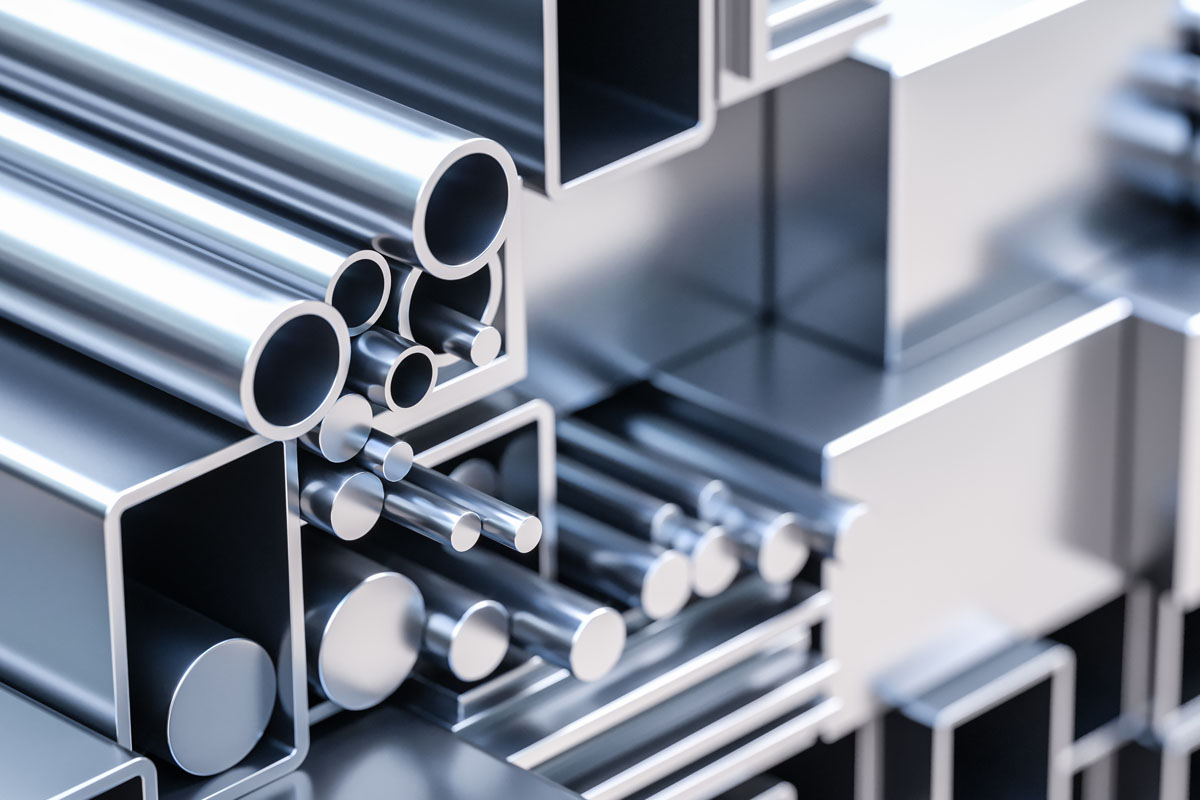

At Aviraj Precision Solutions, working with metals is one of our core competencies. We excel in precision engineering solutions involving various metals, leveraging our expertise and cutting-edge technology to meet the exacting demands of our clients. Our capabilities in working with metals encompass a wide range of industries, including aerospace, automotive, medical, electronics, and more.

At Aviraj Precision Solutions, we specialize in working with a variety of metals, including Magnesium Alloys. Magnesium Alloys are known for their excellent strength-to-weight ratio, making them a popular choice in industries where lightweight and high-performance materials are essential. Here are some of the key features and specialties of Aviraj Precision Solutions when it comes to manufacturing with Magnesium Alloys :

Precision Machining : Aviraj Precision Solutions employ advanced precision machining techniques to shape Magnesium Alloy components with utmost accuracy and consistency. Our state-of-the-art CNC machines and expert operators ensure that the finished products meet the most stringent tolerances and specifications.

Material Expertise : Our team has an in-depth understanding of the properties and behavior of Magnesium Alloys, allowing us to optimize the manufacturing process for each specific alloy variant. This expertise ensures that we deliver components that meet the highest standards of quality and performance.

Custom Solutions : Aviraj Precision Solutions recognize that every client's project has unique requirements. Our approach is tailored to meet your specific needs, whether it's a prototype development or large-scale production. We work closely with our clients to understand their objectives and provide tailored solutions that align with their goals.

Quality Assurance : At Aviraj Precision Solutions, quality is at the core of everything we do. Our stringent quality control measures and inspection processes ensure that each Magnesium Alloy component leaving our facility meets the highest quality standards.

Technical Specifications : Magnesium alloys are lightweight materials with a density ranging from 1.7 to 2.0 g/cm³. The melting point of magnesium varies depending on the alloy composition but typically falls between 650-950°C

Applications : Magnesium alloys are widely used in industries such as automotive, aerospace, and electronics. They are employed for manufacturing lightweight components, such as car parts, aircraft frames, laptops, and portable electronic devices, where weight reduction is crucial.

Copyright © Aviraj Precision Solutions, All Right Reserved.

Designed By Collin IT Solution