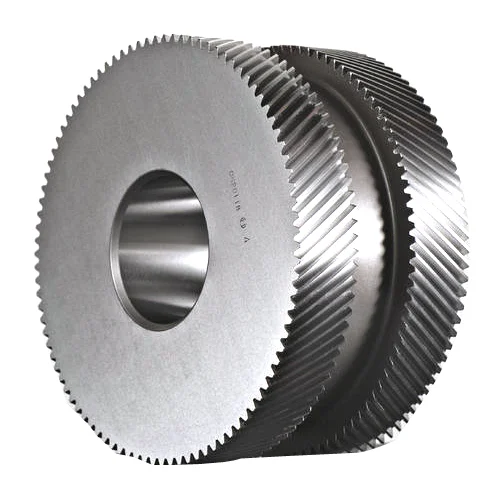

Aviraj Precision Solutions specializes in manufacturing customizable double helical gears, designed to meet the specific requirements of various industries. Double helical gears are a type of helical gear where the teeth are arranged in two opposing sets, forming a V-shape. This design helps to counteract axial forces and provides smoother operation compared to single helical gears.

Tooth Design: Double helical gears have two sets of helical teeth that are cut in opposite directions. This design creates a V-shaped tooth pattern, which helps to balance axial forces and provide smooth and continuous engagement.

Load Distribution: The dual helix design allows for even load distribution across multiple teeth. This characteristic reduces the impact on individual teeth and enhances the gear's ability to handle higher loads.

Manufacturing Expertise: Aviraj Precision Solutions excels in the precision manufacturing of double helical gears, ensuring that each gear is produced with high accuracy and meets strict tolerances for optimal performance.

Material Selection: The choice of materials for double helical gears is crucial for their performance and longevity. Aviraj Precision Solutions selects high-quality materials that offer strength, wear resistance, and durability based on specific application needs.

Gear Ratio Flexibility: Double helical gears can be designed to achieve a range of gear ratios, providing flexibility in speed and torque control. Aviraj Precision Solutions customizes gear ratios to meet specific application requirements.

Applications: Double helical gears are used in various mechanical systems where high load capacity and smooth operation are required. Common applications include heavy machinery, automotive transmissions, and high-torque industrial equipment.

Alignment and Accuracy: Accurate alignment between double helical gears is essential for smooth operation and to minimize wear. Aviraj Precision Solutions focuses on achieving precise alignment and maintaining tight tolerances during the manufacturing process.

Maintenance and Longevity: Double helical gears are generally robust and require minimal maintenance due to their durable design and reliable performance. Aviraj Precision Solutions emphasizes the creation of long-lasting gears that reduce the need for frequent maintenance.

Tooth Profile:The tooth profile of double helical gears is designed to ensure effective meshing and power transmission. Aviraj Precision Solutions tailors the tooth profile to optimize performance based on specific application needs.

Copyright © Aviraj Precision Solutions, All Right Reserved.

Designed By Collin IT Solution