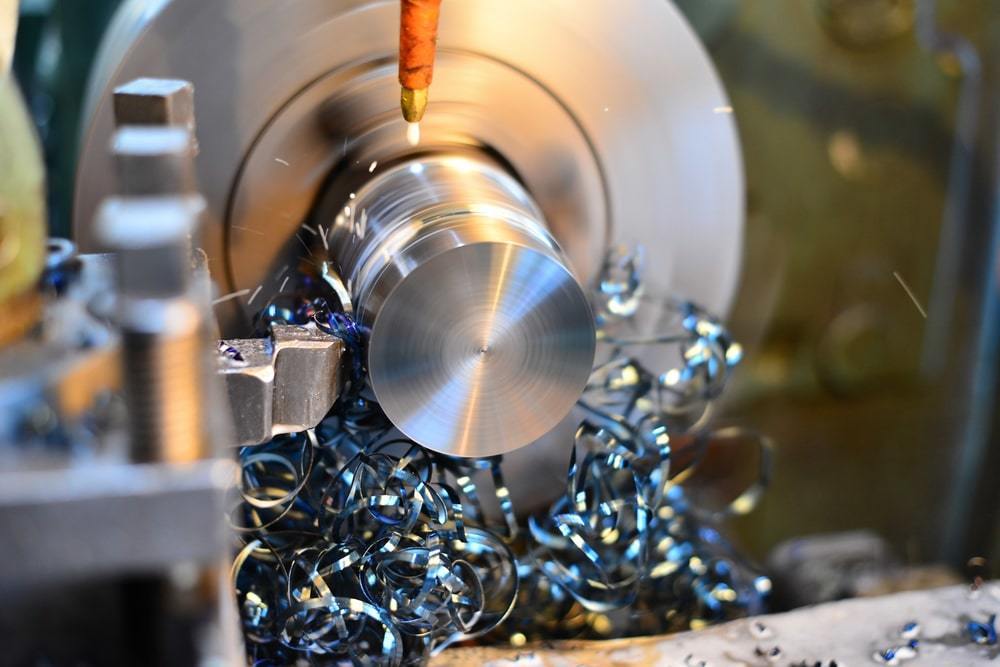

Machining is a fundamental manufacturing process that involves shaping, cutting, and finishing materials, typically metals, to create precise components and parts. This process is crucial in producing high-quality, accurate, and consistent products across various industries. Aviraj Precision Solutions excels in providing advanced machining services tailored to meet the diverse needs of its clients.

Process Overview:

Types of Machining Techniques:

Material Considerations:

Tooling:

Copyright © Aviraj Precision Solutions, All Right Reserved.

Designed By Collin IT Solution