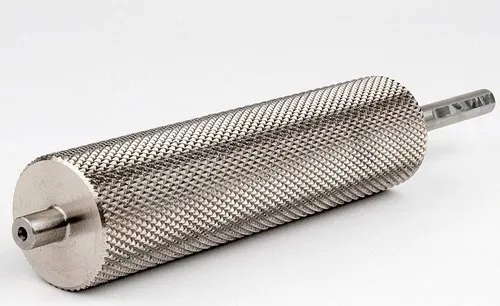

Aviraj Precision Solutions specializes in manufacturing customizable drive rollers, designed to meet the specific requirements of various industries. Drive rollers are a crucial component of conveyor systems and other machinery, responsible for transmitting power and driving the movement of belts, chains, or other materials. These rollers are engineered for high performance, durability, and precision, ensuring efficient and reliable operation.

Material Selection: Drive rollers are typically made from materials such as steel, rubber, or polyurethane. Aviraj Precision Solutions selects materials based on the application’s demands, ensuring resistance to wear, impact, and environmental factors. The choice of material is critical for the roller's longevity and performance, particularly in high-stress environments.

Roller Diameter : The diameter of the drive roller directly affects the speed and torque transmitted to the conveyor or machinery. Aviraj Precision Solutions offers a range of diameters to suit different operational requirements, ensuring the right balance between speed and power.

Axle Design : The axle of the drive roller is crucial for its stability and performance. Aviraj Precision Solutions offers various axle designs, including fixed and adjustable options, to ensure proper support and alignment within different systems.

Bearings : High-quality bearings are integral to the performance of drive rollers. Aviraj Precision Solutions incorporates precision bearings that reduce friction and wear, ensuring smooth and efficient rotation even under heavy loads.

Customization : Drive rollers can be customized in terms of size, material, coating, and mounting configuration to meet the specific needs of different industries. Aviraj Precision Solutions works closely with clients to design rollers that perfectly align with their operational requirements.

Surface Coating : Depending on the application, drive rollers can be coated with specialized materials to enhance grip, reduce wear, and improve overall performance. Coatings such as rubber or polyurethane provide additional friction, which is essential for driving belts or other components without slippage.

Alignment and Tracking : Proper alignment and tracking of drive rollers are essential to prevent belt slippage and ensure consistent movement. Aviraj Precision Solutions designs drive rollers with precision to maintain proper alignment, reducing the risk of operational disruptions.

Applications : Drive rollers are used across various industries, including manufacturing, logistics, packaging, automotive, and more. They play a key role in ensuring the smooth and efficient movement of materials, contributing to overall system productivity.

Copyright © Aviraj Precision Solutions, All Right Reserved.

Designed By Collin IT Solution