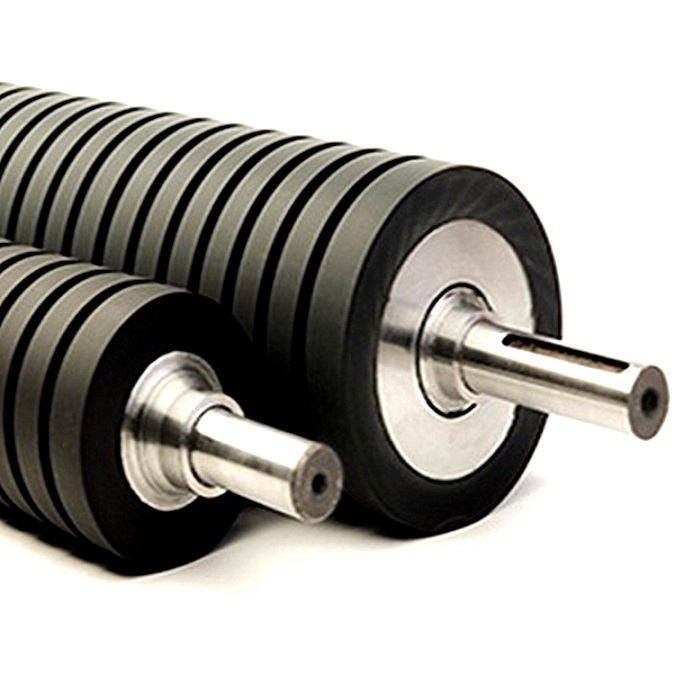

Aviraj Precision Solutions specializes in manufacturing high-quality precision rollers designed to meet the stringent requirements of various industries. Precision rollers are critical components in machinery where exacting standards of performance, reliability, and consistency are required. These rollers are engineered with tight tolerances and superior materials to ensure optimal operation in demanding applications.

Material Selection: The choice of materials for precision rollers is crucial for their performance. Aviraj Precision Solutions selects materials such as hardened steel, stainless steel, aluminum, and advanced polymers based on the specific requirements of the application, ensuring durability, wear resistance, and longevity.

Dimensional Accuracy: Precision rollers are manufactured with extremely tight tolerances to ensure they meet the exact specifications needed for their application. Aviraj Precision Solutions emphasizes dimensional accuracy in their production process, ensuring that each roller performs flawlessly within its intended system.

Load Capacity: Precision rollers are designed to handle significant loads while maintaining their structural integrity and performance. Aviraj Precision Solutions engineers these rollers to meet the load-bearing requirements of their specific application, ensuring reliable operation under heavy or continuous loads.

Bearings Integration : High-quality bearings are essential for the smooth operation of precision rollers. Aviraj Precision Solutions incorporates advanced bearings into their rollers to ensure low friction, reduced wear, and long-lasting performance.

Customization : Precision rollers can be customized in terms of size, material, surface treatment, and other features to meet the unique needs of different industries. Aviraj Precision Solutions offers extensive customization options to ensure that each roller fits perfectly within its intended system.

Surface Finish : The surface finish of precision rollers is critical to their performance, particularly in applications requiring minimal friction and wear. Aviraj Precision Solutions ensures a high-quality finish, often polished or coated, to enhance the roller's performance and reduce the risk of surface defects.

Coatings and Surface Treatments: Surface treatments such as hardening, plating, or coating are often applied to precision rollers to enhance their wear resistance, corrosion resistance, or reduce friction. Aviraj Precision Solutions offers a range of surface treatments tailored to the application's environmental conditions and performance requirements.

Temperature Resistance: Precision rollers may be required to operate in high or low-temperature environments. Aviraj Precision Solutions designs rollers with materials and coatings that can withstand extreme temperatures, ensuring consistent performance across a wide range of conditions.

Wear Resistance: Precision rollers are subject to continuous use in demanding environments. Aviraj Precision Solutions employs advanced manufacturing techniques and material treatments to enhance the wear resistance of these rollers, ensuring they maintain their performance over an extended period.

Applications : Precision rollers are used in a variety of applications, including printing presses, conveyor systems, textile machinery, packaging equipment, and more. Their ability to provide reliable, precise movement makes them essential in many industrial processes.

Copyright © Aviraj Precision Solutions, All Right Reserved.

Designed By Collin IT Solution